Computer numerical control (CNC) machined parts can often vary in complexity. From simple flat parts to sophisticated and highly complex curved geometries, it is important to choose the right CNC Machining Services Sydney for the job. There are different types of CNC machines and can be used for different parts.

The type of machine used (a CNC lathe, 3-axis CNC milling machine, or a 5-axis machining center) is usually determined by the complexity of the part. The complexity, geometry, and dimensions of parts influence the type of machine selected, along with tolerances, product end-use, and material type.

In general, a more complex part will need to be taken into account when machining due to its design, dimensions, and specific requirements. Designers should always work whenever possible to create simple, easy-to-produce parts while the part is in the design process. The simpler the design, the easier it will be to CNC Routing Sydney manufacture it, and the cheaper the overall costs will be by default.

Mechanical designers are always considering how you can create designs that require fewer components while offering maximum performance. This can reduce costs while ensuring efficiency and the highest performance.

Component complexity is always a consideration for mechanical designers, and efficiently designed high-performance components take into account the delivery time of Machining Services Sydney. It is possible to reduce the risk caused by human error.

Minor errors in measurement, execution, or production can cause projects and products to be completely affected. With this in mind, it is worth making sure to work with experienced designers, engineers, and manufacturers. However, sometimes complex Computer numerical control (CNC) machining is required, in which a high degree of precision and finish can result in a longer delivery time.

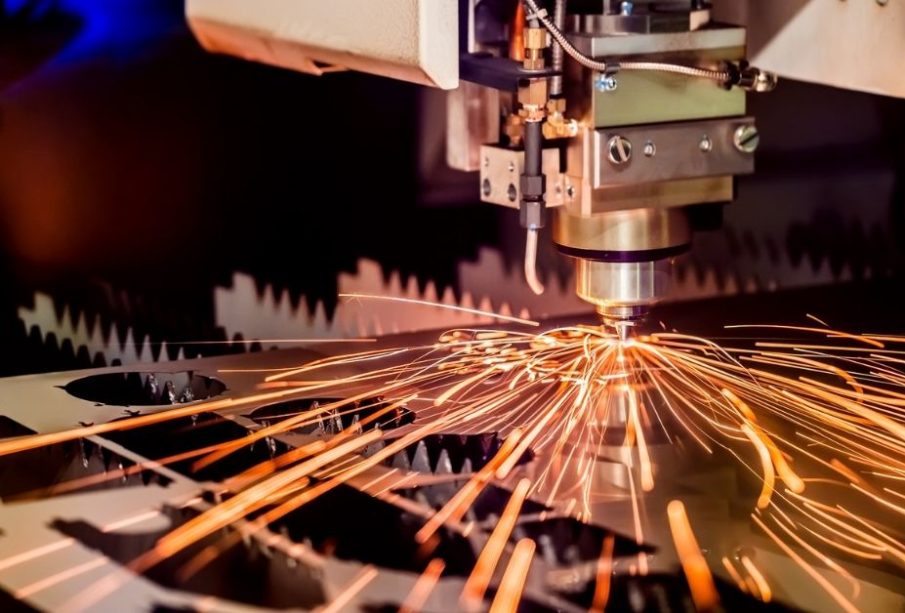

The general rule is that 5-axis CNC machining is required for complex parts and complex shapes. This is because the machine can work on 5 different axes/axes to achieve the final shape instead of two or three that operate only with X and Y. By installing another three axes, A, B, and C, you can machine more precise and complex parts without having the part manually inside the Metal Engineering Sydney. The fact that 5-axis Computer numerical control (CNC) milling can offer a “single configuration” is a big advantage that reduces time.

The high precision of tools and experienced operators can help produce the required part with high precision results and fast delivery time. It is always worth contacting an experienced manufacturer to ask about their editing options and how they can best help you.

An inspection of the coordinate measuring machine (CMM) involves using a coordinate measuring machine to check the dimensions of a part and determine whether a part meets certain tolerance requirements.

A coordinate measuring machine is used to measure the quality and properties of an object. CMM inspection is necessary to measure more complex parts to ensure that they meet specifications. They are often included for high-precision parts that require the latest in quality and precision Plastic Manufacturers Sydney. Smooth surfaces are also checked at this point to make sure they match the drawings and design.

A CMM works with a probe that measures the points of a workpiece. 3 axes form the coordinate system of the machine. The other system is the part coordinate system in which the 3 axes refer to the features and date of the workpiece.